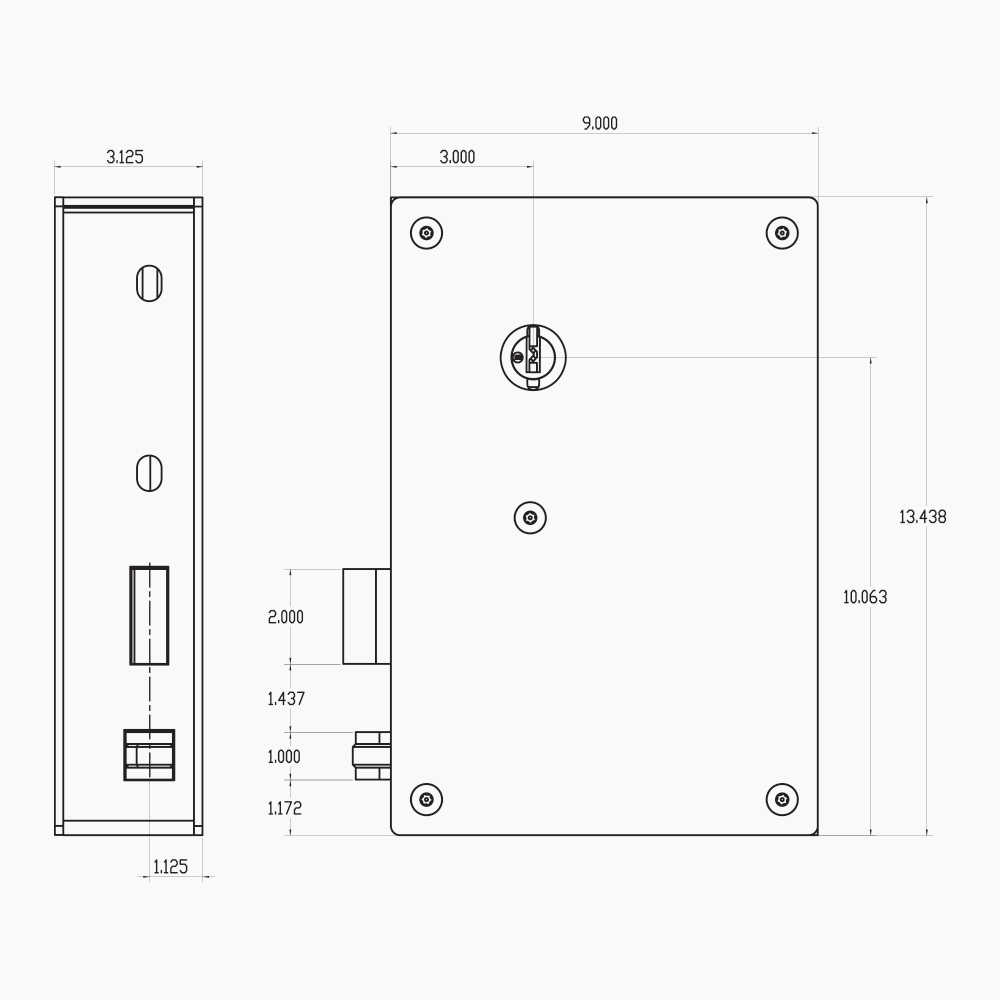

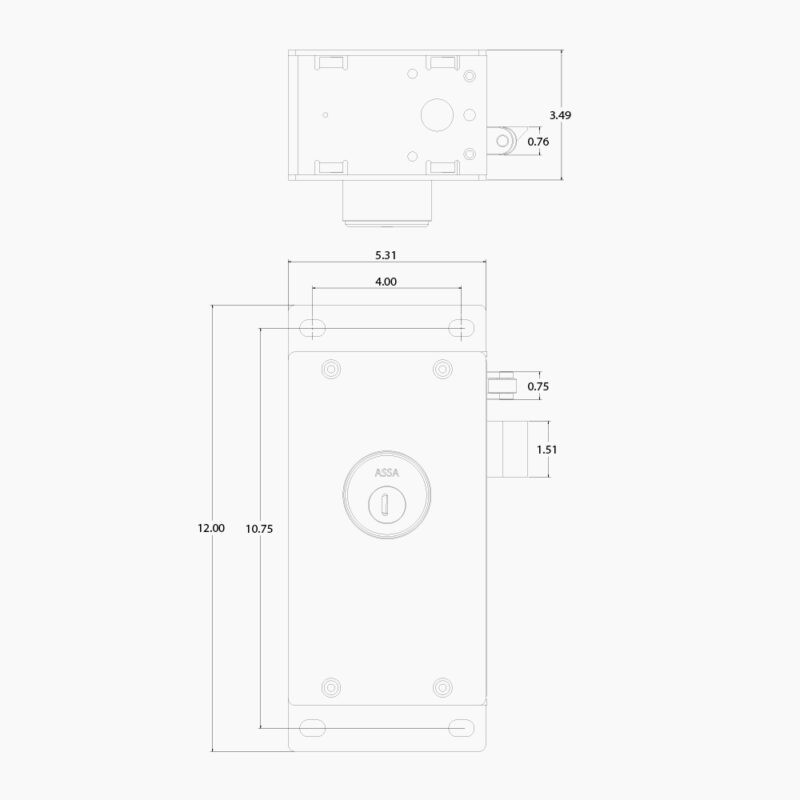

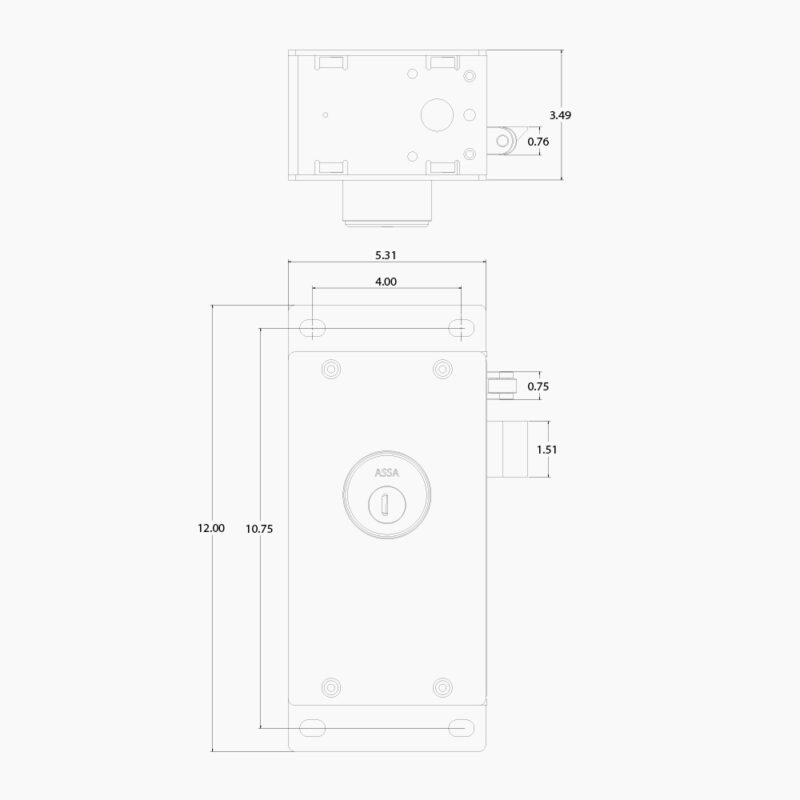

51M Motor-Operated Deadlatch

The 51M is a motor operated lever tumbler lock designed for a variety of swing door applications such as inmate rooms, housing and dayroom perimeter doors, corridors and exterior doors.

Operation Details

The 51M deadlatch is a motor operated lock. When the door is in a locked closed condition, the latchbolt is deadlocked preventing the latchbolt from being retracted. Once the motor is energized, the deadlatch is lifted and the latchbolt is allowed to retract, unlocking the lock. The motor is equipped with a motor switch that allows for full cycle operation. Full cycle (M) operation uses a momentary contact to rotate the motor 360 degrees and unlock the lock.

Once the door opens, the latch will project and the lock will return to a locked condition once the door is closed. Full cycle typically uses the “Mechanical Holdback” feature as described below. The deadlock indicator switch provides monitoring of the deadlocked condition as well as the full projection of the latchbolt. When ordering, the full cycle lock is usually specified as having “Mechanical Holdback”, which allows the bolt to be retracted until the door opens.

51M Motor-Operated Deadlatch

- Jamb Mounted For Swing Doors

- Security: Maximum

- Key: Paracentric

- 24VDC or 120VAC Motor

Choice of Function

Mechanical Holdback (Standard) - Once unlocked, the latchbolt is held retracted until the door opens. The latchbolt then projects and allows the door to be slammed and relocked.

Non-Holdback (Optional) - Latchbolt retracts only through the full cycle operation.

51M Motor-Operated Deadlatch

Standard Features

- 120 VAC or 24 VDC Motor

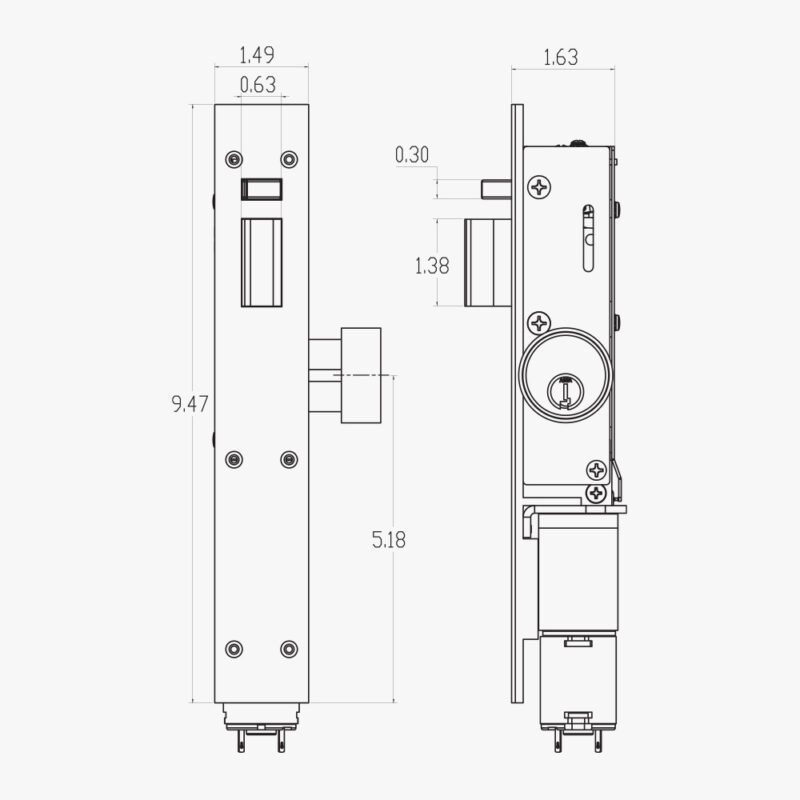

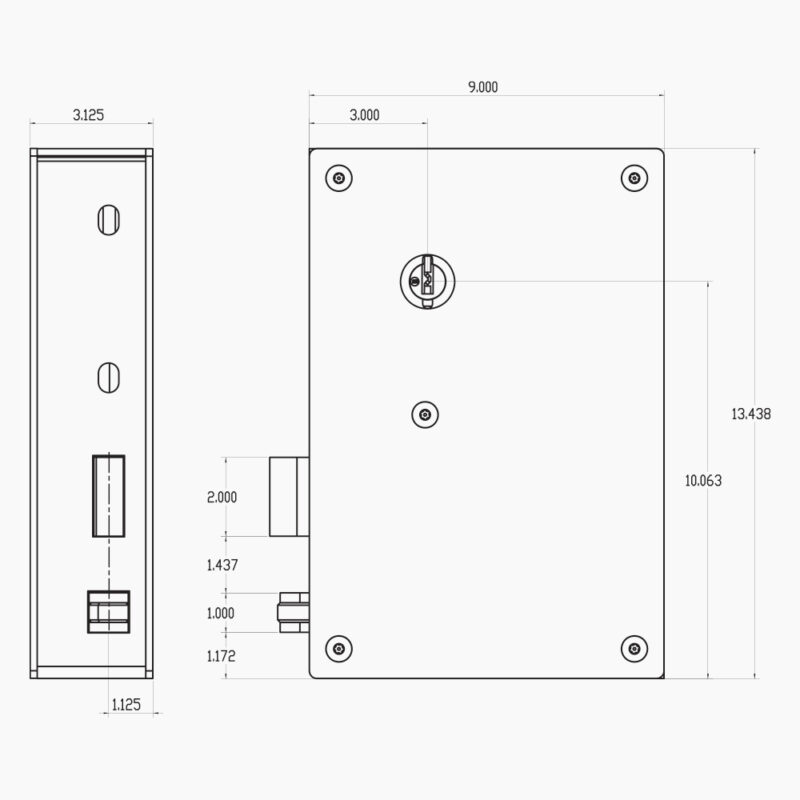

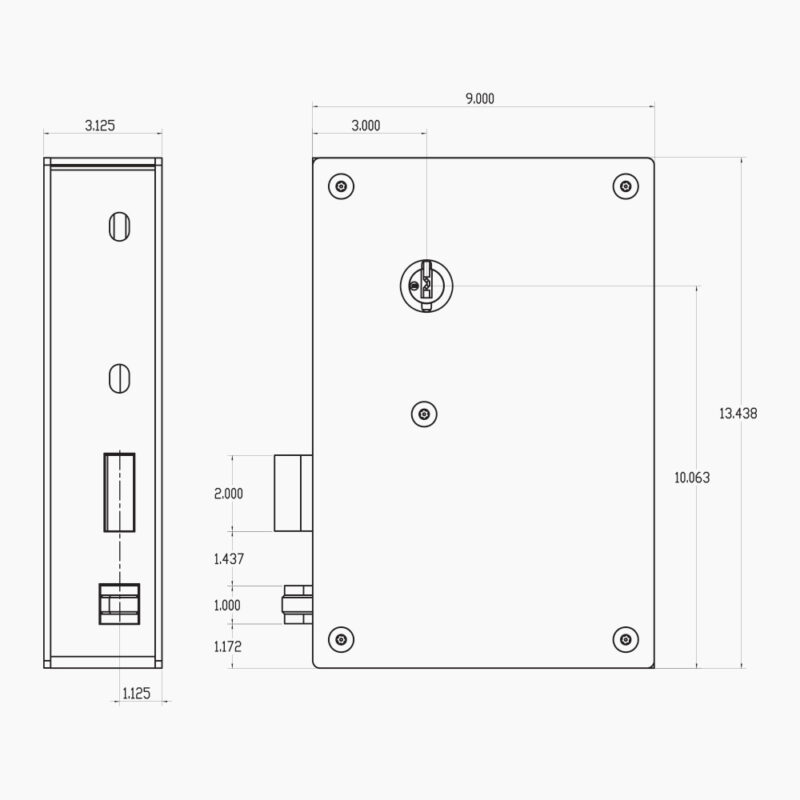

- 3/4” Throw Latchbolt

- Deadlock Indicator Switch

- Heavy Duty Construction

- Adjustable Roller Bolt

- Corrosive Resistant Parts

- Internal Mounting Holes

- Manual Key Release

- Easy Wiring Field Plug

Component Specifications

- Motor - 120 VAC 60 Hz or 24 VDC

- Reinforced Backplate - 1/2” Steel Perimeter Guides

- 7 Gauge Steel - Zinc Plated Case & Cover

- Latchbolt - Hardened Steel Roller Pins

- Deadlock Lever - Zinc Plated Steel

- Operating Lever - 1/2” Zinc Plated Steel

- Springs - Stainless Steel

Keying

- Available 5 or 6 Tumbler

(See Handing Chart)